Preparation technology and application of solid recovered fuels from municipal solid wastes

-

摘要:

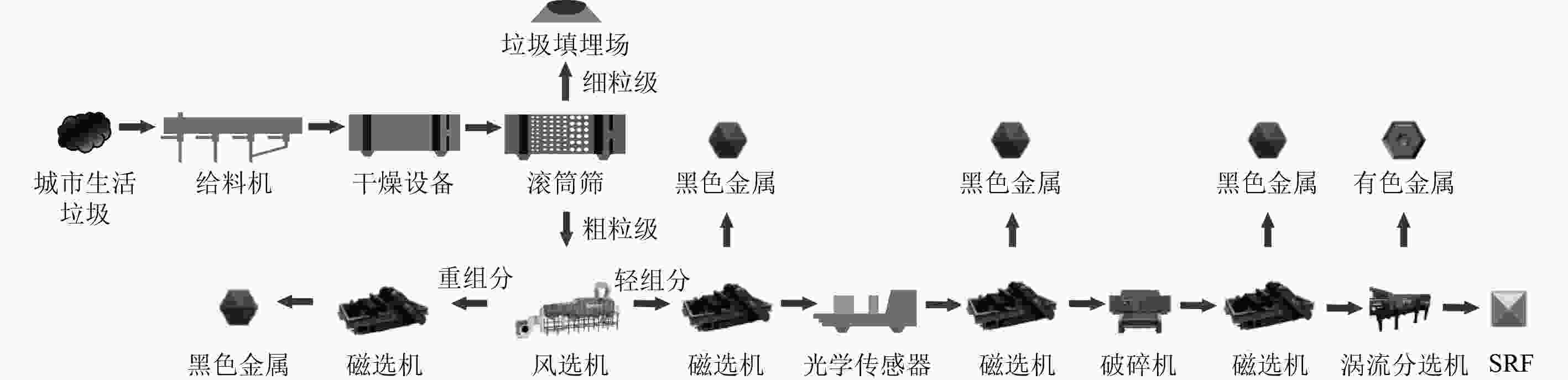

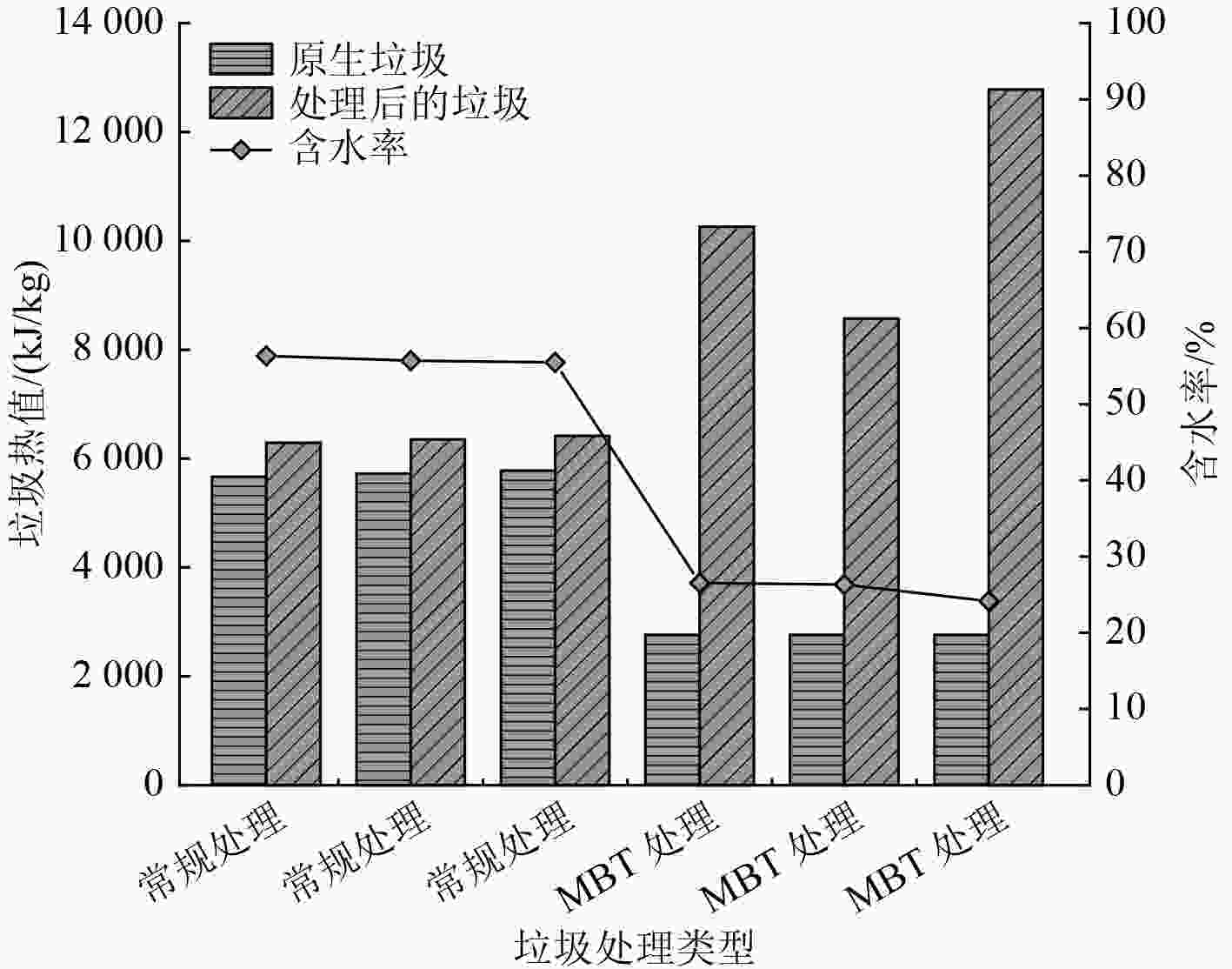

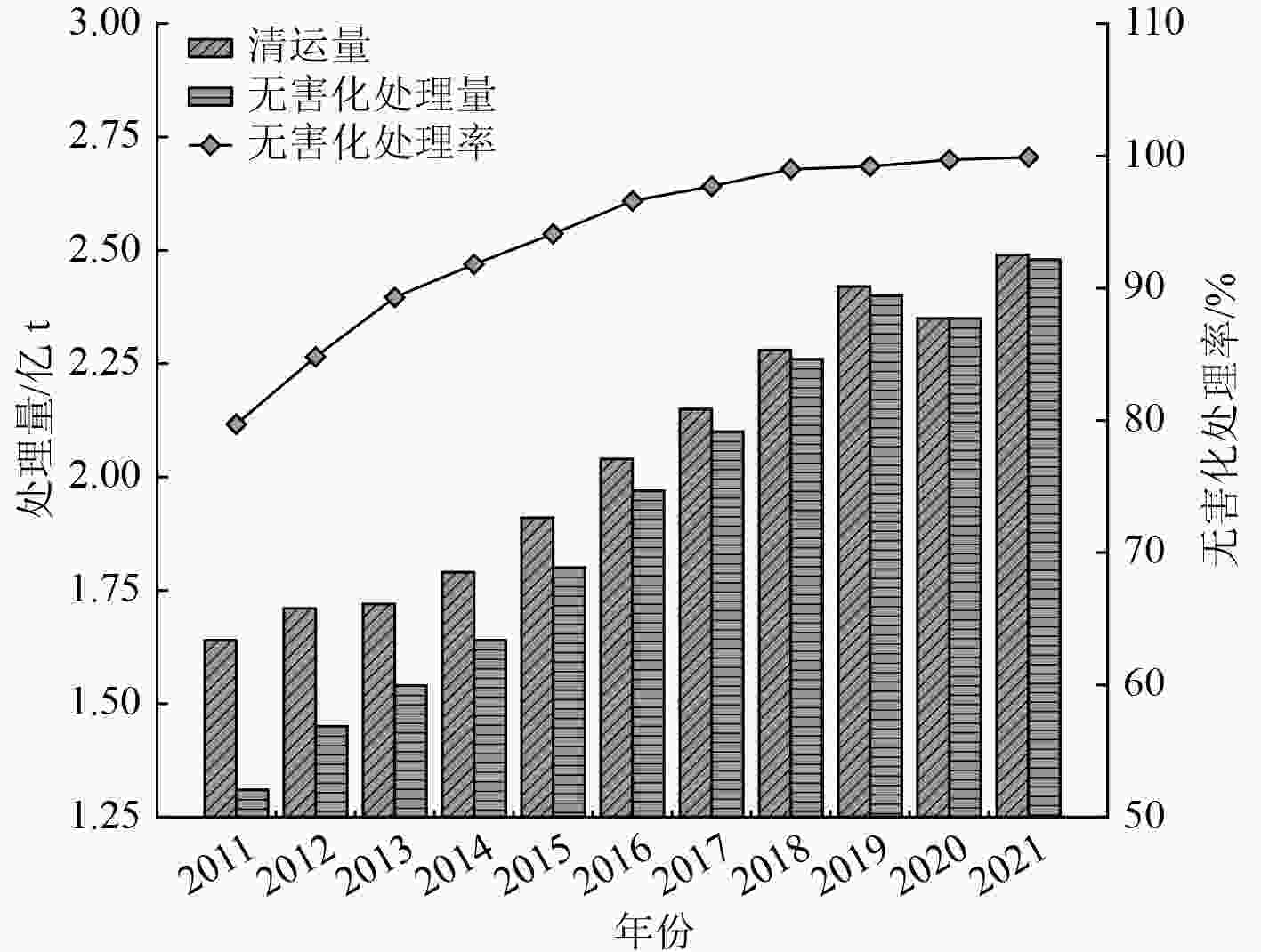

针对城市生活垃圾等固废产生量日益增多、组分复杂,处置时易产生温室气体,对其有效管理和碳减排成为当前关注的热点。介绍了城市生活垃圾处理现状及国内外固体替代燃料标准,叙述机械生物处理技术中包含的生物干化、机械分选技术等工序,分析了固体替代燃料燃烧过程中存在的潜在问题,结合城市生活垃圾常规处理和机械生物处理工艺效果,获得机械生物处理后的固体替代燃料热值达到10 536 kJ/kg,比原生垃圾热值提升了3倍,且不需要添加辅助燃料进行燃烧。固体替代燃料在水泥、电力等行业应用能提高资源有效再利用,减少化石燃料的使用,对节约成本、保护环境以及推进我国垃圾分类和碳中和进程具有重要意义。

-

关键词:

- 城市生活垃圾 /

- 固体替代燃料(SRF) /

- 机械生物处理 /

- 热值

Abstract:Solid wastes such as municipal solid wastes (MSWs) are increasingly produced with complex components, and greenhouse gases are generated in the process of disposal, so the effective management of such solid wastes and the carbon emission reduction have become a hot topic of current concern.The current status of MSWs treatment and the standards of solid recovered fuels at home and abroad were introduced, the processes of biological drying and mechanical sorting technology included in the mechanical biological treatment technologies were described, and the potential problems in the combustion process of solid recovered fuels were analyzed. Combining the effects of conventional treatment and mechanical biological treatment of MSWs, the calorific value of solid recovered fuels after mechanical biological treatment was obtained to reach 10 536 kJ/kg, which was three times higher than the calorific value of virgin waste and did not require the addition of auxiliary fuel for combustion. The application of solid recovered fuels in cement and electric power industries could improve the effective reuse of resources and reduce the use of fossil fuels, which was important for cost saving, environmental protection and promoting the process of waste separation and carbon neutrality in China.

-

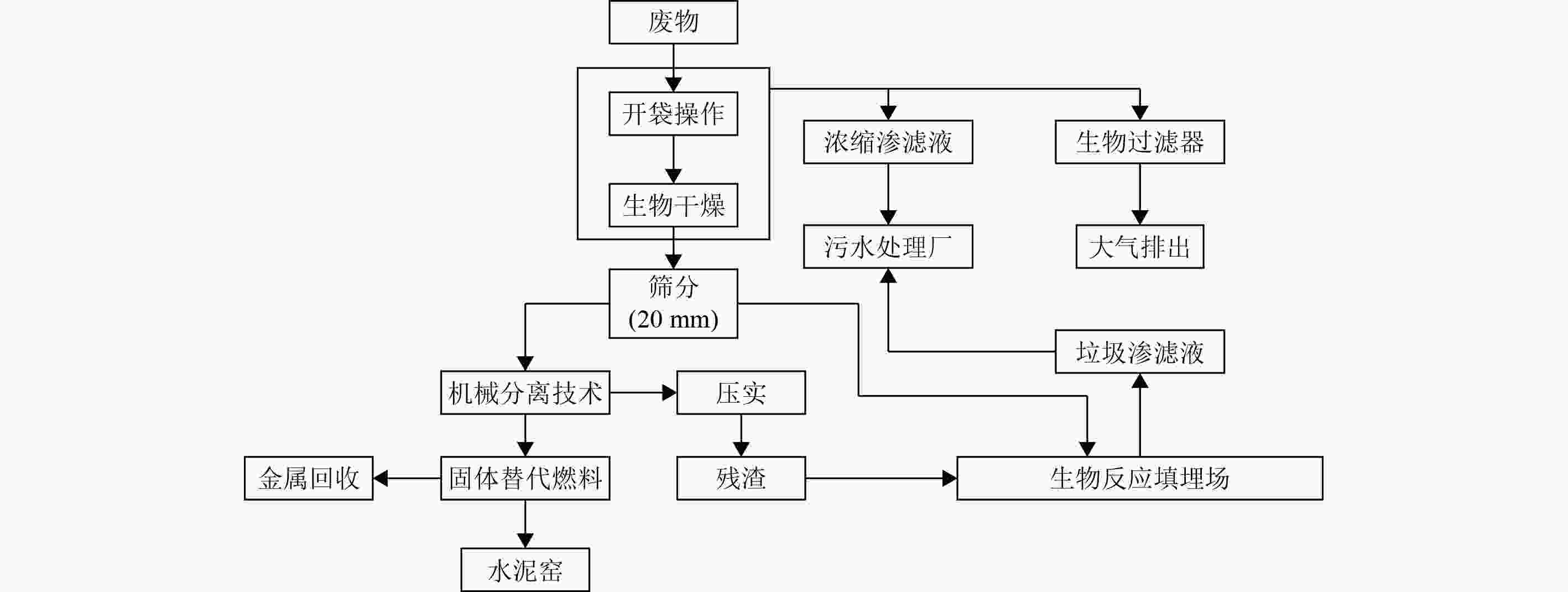

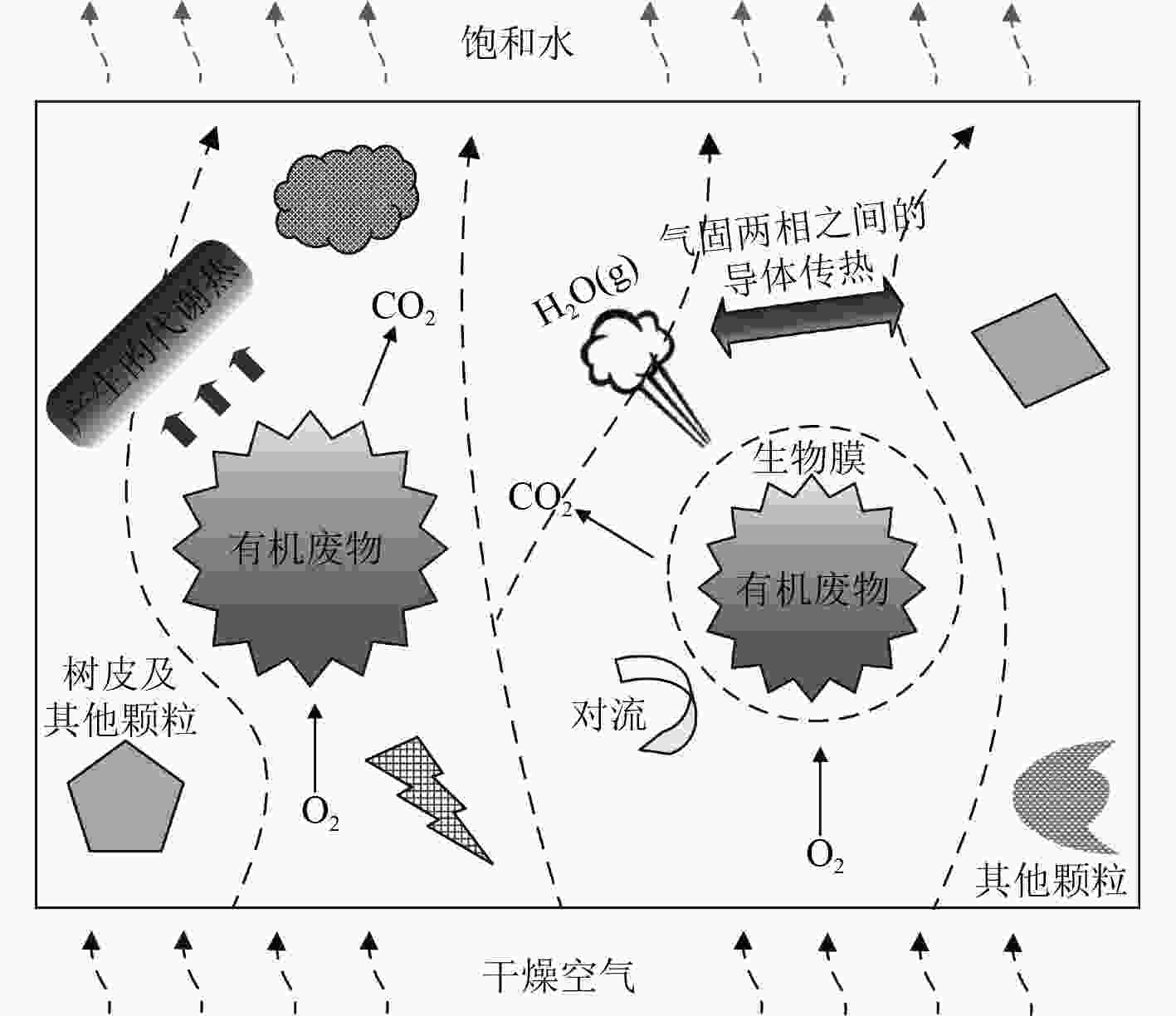

图 3 生物干化过程示意[15]

Figure 3. Schematic diagram of biological drying process

表 1 我国不同城市生活垃圾物理组分占比

Table 1. The proportion of physical components of different municipal solid wastes in China

% 表 2 贵州省黔南州罗甸县城市生活垃圾组成

Table 2. Analysis of municipal waste composition in Luodian County, Qiannan Prefecture,Guizhou province

% 类别 生活垃圾 沙土 玻璃 金属 纸 塑料 橡胶 布 草木 厨余 白塑料 总水分 收到基成分 10.30 1.26 0.59 18.51 13.30 0.00 2.89 5.48 47.28 0.39 总成分 100 6.29 1.13 0.53 10.07 7.07 0.00 1.80 2.84 13.64 0.29 56.34 干基成分 100 14.41 2.58 1.21 23.06 16.20 0.00 4.12 6.49 31.25 0.68 可燃组分干基成分 28.19 19.81 0.00 5.03 7.94 38.21 0.83 表 3 SRF的产品分级

Table 3. Product classification of SRF

分级特性 统计度量 单位 分级 低位热值

(QARB)平均值 MJ/kg Q1 Q2 Q3 Q4 Q5 ≥25 20~25 15~20 10~15 3~10 氯含量

(ClADB)平均值 % L1 L2 L3 L4 L5 ≤0.50 0.5~1.0 1.0~1.5 1.5~2.0 >2.0 汞含量

(HgARB)中位数 μg/g G1 G2 G3 G4 G5 ≤0.40 0.40~0.60 0.60~0.80 0.80~1.0 1.0~2.0 表 4 MBT工厂处理后SRF的特征

Table 4. Effect of SRF after MBT plant treatment

测试项目 含水率 / % 热值 / (kJ/kg) 灰分占比 / % 细物料 28.22 4777 38.20 SRF 25.67 10536 23.16 表 5 SRF共燃中存在的潜在问题

Table 5. Potential problems in SRF co-combustion

质量因素 产生现象 氯含量 氯含量过高会导致锅炉钢的腐蚀,排放出高酸性气体(如氯化氢),导致多氯代二苯并-对-二噁英(PCDDs)的形成 热值 SRF比均质材料更难燃烧,且燃烧不充分 灰分含量 灰分容易导致结垢和结渣,SRF共燃产生的灰分

含量可能比煤要高4~6 倍 -

[1] 国家统计局. 中国统计年鉴[M]. 北京: 中国统计出版社, 2022. [2] 周晓萃, 徐琳瑜, 杨志峰. 城市生活垃圾处理全过程的低碳模式优化研究[J]. 环境科学学报,2012,32(2):498-505.ZHOU X C, XU L Y, YANG Z F. Optimization of low-carbon municipal solid waste processing model[J]. Acta Scientiae Circumstantiae,2012,32(2):498-505. [3] 姜华, 李艳萍, 高健, 等. 关于统筹建立二氧化碳排放总量控制制度的思考[J]. 环境工程技术学报,2022,12(1):1-5.JIANG H, LI Y P, GAO J, et al. Thoughts on the overall establishment of total carbon dioxide emission control system[J]. Journal of Environmental Engineering Technology,2022,12(1):1-5. [4] 张钊. 生活垃圾处理的碳排放和减排策略[J]. 皮革制作与环保科技,2021,2(20):92-93.ZHANG Z. Carbon emission and emission reduction strategy of domestic waste treatment[J]. Leather Manufacture and Environmental Technology,2021,2(20):92-93. [5] 任中山, 陈瑛, 王永明, 等. 生活垃圾分类对垃圾焚烧发电产业发展影响的分析[J]. 环境工程,2021,39(6):150-153.REN Z S, CHEN Y, WANG Y M, et al. Analysis of influence of domestic waste classification on development of waste incineration power generation industry in China[J]. Environmental Engineering,2021,39(6):150-153. [6] 张兰霞, 李国学, 罗文海, 等. 北京城乡不同功能区生活垃圾组成特性及分类研究[J]. 环境卫生工程,2020,28(6):15-21.ZHANG L X, LI G X, LUO W H, et al. Study on the composition characteristics and classification of MSW in different functional zones in Beijing urban and rural[J]. Environmental Sanitation Engineering,2020,28(6):15-21. [7] 粟颖. 广东省城市生活垃圾组分分析及对垃圾分类的启示[J]. 再生资源与循环经济,2021,14(11):21-24.SU Y. Analysis on the component of municipal solid waste in Guangdong Province and its enlightenment on waste classification[J]. Recycling Research,2021,14(11):21-24. [8] 李美叶, 郑振涛. 济南市生活垃圾性状变化趋势及处理技术多元化转型分析[J]. 环境卫生工程,2014,22(4):62-64.LI M Y, ZHENG Z T. Property change of domestic waste and diversified transition of treatment technologies in Jinan[J]. Environmental Sanitation Engineering,2014,22(4):62-64. [9] 隋儒楠. 沈阳市城市和农村生活垃圾物理组分调查与源头分类研究[J]. 区域治理,2019(11):238.SUI R N. Investigation on physical composition and source classification of urban and rural domestic waste in Shenyang[J]. Regional Govenance,2019(11):238. [10] 聂发辉, 周永希, 张后虎, 等. 垃圾填埋场甲烷释放及氧化技术研究进展[J]. 环境工程技术学报,2016,6(2):163-169.NIE F H, ZHOU Y X, ZHANG H H, et al. Research progress on CH4 emissions and oxidation process in the landfill[J]. Journal of Environmental Engineering Technology,2016,6(2):163-169. [11] 吴一鸣, 周怡静, 田贺忠, 等. 我国城市生活垃圾处理处置全过程大气排放研究进展[J]. 环境科学研究,2018,31(6):991-999.WU Y M, ZHOU Y J, TIAN H Z, et al. Research advances of atmospheric emission from the whole process of municipal solid waste treatment and disposal in China[J]. Research of Environmental Sciences,2018,31(6):991-999. [12] 罗家强. 生活垃圾机械-生物处理技术研究[J]. 中国资源综合利用,2018,36(8):77-79.LUO J Q. Domestic waste mechanical-biological treatment technology research[J]. China Resources Comprehensive Utilization,2018,36(8):77-79. [13] GROSSO M, DELLAVEDOVA S, RIGAMONTI L, et al. Case study of an MBT plant producing SRF for cement kiln co-combustion, coupled with a bioreactor landfill for process residues[J]. Waste Management,2016,47:267-275. doi: 10.1016/j.wasman.2015.10.017 [14] 任超峰, 方朝军, 夏小栋, 等. 城市生活垃圾固体回收燃料在中国的发展前景[J]. 现代化工,2019,39(9):1-4.REN C F, FANG C J, XIA X D, et al. Development prospect of solid recovery fuels from municipal solid wastes in China[J]. Modern Chemical Industry,2019,39(9):1-4. [15] NAVAEE-ARDEH S, BERTRAND F, STUART P R. Development and experimental evaluation of a 1D distributed model of transport phenomena in a continuous biodrying process for pulp and paper mixed sludge[J]. Drying Technology,2011,29(2):135-152. doi: 10.1080/07373937.2010.482723 [16] VELIS C A, LONGHURST P J, DREW G H, et al. Biodrying for mechanical–biological treatment of wastes: a review of process science and engineering[J]. Bioresource Technology,2009,100(11):2747-2761. doi: 10.1016/j.biortech.2008.12.026 [17] 夏亚穆, 王伟, 毕文慧. 生物干燥处理城市垃圾技术的研究进展[J]. 氨基酸和生物资源,2009,31(4):39-42.XIA Y M, WANG W, BI W H. Advances of bio-drying treatment of municipal wastes[J]. Amino Acids and Biotic Resources,2009,31(4):39-42. [18] ZHANG D Q, ZHANG H, WU C L, et al. Evolution of heavy metals in municipal solid waste during bio-drying and implications of their subsequent transfer during combustion[J]. Waste Management,2011,31(8):1790-1796. doi: 10.1016/j.wasman.2011.04.006 [19] YANG B Q, HAO Z D, JAHNG D. Advances in biodrying technologies for converting organic wastes into solid fuel[J]. Drying Technology,2017,35(16):1950-1969. doi: 10.1080/07373937.2017.1322100 [20] BILGIN M, TULUN Ş. Biodrying for municipal solid waste: volume and weight reduction[J]. Environmental Technology,2015,36(13):1691-1697. doi: 10.1080/09593330.2015.1006262 [21] ZHANG D Q, HE P J, JIN T F, et al. Bio-drying of municipal solid waste with high water content by aeration procedures regulation and inoculation[J]. Bioresource Technology,2008,99(18):8796-8802. doi: 10.1016/j.biortech.2008.04.046 [22] 周天津. 浅谈锤式破碎机[J]. 砖瓦,2018(2):30-31.ZHOU T J. Brief introduction on hammer crusher[J]. Block-Brick-Tile,2018(2):30-31. [23] 刘得楗. 固体回收燃料(SRF)循环流化床焚烧锅炉设计和运行优化[D]. 杭州: 浙江大学, 2020. [24] VELIS C A, LONGHURST P J, DREW G H, et al. Production and quality assurance of solid recovered fuels using mechanical-biological treatment (MBT) of waste: a comprehensive assessment[J]. Critical Reviews in Environmental Science and Technology,2010,40(12):979-1105. doi: 10.1080/10643380802586980 [25] 贺晋瑜, 何捷, 王郁涛, 等. 中国水泥行业二氧化碳排放达峰路径研究[J]. 环境科学研究,2022,35(2):329-338.HE J Y, HE J, WANG Y T, et al. Pathway of carbon emissions peak for cement industry in China[J]. Research of Environmental Sciences,2022,35(2):329-338. [26] MONTANÉ D, ABELLÓ S, FARRIOL X, et al. Volatilization characteristics of solid recovered fuels (SRFs)[J]. Fuel Processing Technology,2013,113:90-96. doi: 10.1016/j.fuproc.2013.03.026 [27] SAMOLADA M C, ZABANIOTOU A A. Energetic valorization of SRF in dedicated plants and cement kilns and guidelines for application in Greece and Cyprus[J]. Resources, Conservation and Recycling,2014,83:34-43. doi: 10.1016/j.resconrec.2013.11.013 [28] GERASSIMIDOU S, VELIS C A, WILLIAMS P T, et al. Chlorine in waste-derived solid recovered fuel (SRF), co-combusted in cement kilns: a systematic review of sources, reactions, fate and implications[J]. Critical Reviews in Environmental Science and Technology,2021,51(2):140-186. doi: 10.1080/10643389.2020.1717298 [29] WOJTACHA-RYCHTER K, KUCHARSKI P, SMOLINSKI A. Conventional and alternative sources of thermal energy in the production of cement: an impact on CO2 emission[J]. Energies,2021,14(6):1539. doi: 10.3390/en14061539 [30] FYFFE J R, BRECKEL A C, TOWNSEND A K, et al. Use of MRF residue as alternative fuel in cement production[J]. Waste Management,2016,47:276-284. doi: 10.1016/j.wasman.2015.05.038 [31] VICZEK S A, ALDRIAN A, POMBERGER R, et al. Determination of the material-recyclable share of SRF during co-processing in the cement industry[J]. Resources, Conservation and Recycling,2020,156:104696. doi: 10.1016/j.resconrec.2020.104696 [32] 蒋旭光, 吴磊, 李晓东, 等. 固体回收燃料焚烧技术的研究现状及发展方向[J]. 环境污染与防治,2018,40(10):1181-1187.JIANG X G, WU L, LI X D, et al. State and developing direction on solid recovered fuel incineration technology[J]. Environmental Pollution and Control,2018,40(10):1181-1187. [33] GARG A, SMITH R, HILL D, et al. An integrated appraisal of energy recovery options in the United Kingdom using solid recovered fuel derived from municipal solid waste[J]. Waste Management,2009,29(8):2289-2297. doi: 10.1016/j.wasman.2009.03.031 [34] WAGLAND S T, KILGALLON P, COVENEY R, et al. Comparison of coal/solid recovered fuel (SRF) with coal/refuse derived fuel (RDF) in a fluidised bed reactor[J]. Waste Management,2011,31(6):1176-1183. doi: 10.1016/j.wasman.2011.01.001 [35] di LONARDO M C, LOMBARDI F, GAVASCI R. Characterization of MBT plants input and outputs: a review[J]. Reviews in Environmental Science and Bio/Technology,2012,11(4):353-363. doi: 10.1007/s11157-012-9299-2 [36] DUNNU G, MAIER J, SCHEFFKNECHT G. Ash fusibility and compositional data of solid recovered fuels[J]. Fuel,2010,89(7):1534-1540. doi: 10.1016/j.fuel.2009.09.008 [37] PEDERSEN M N, JENSEN P A, HJULER K, et al. Agglomeration and deposition behavior of solid recovered fuel[J]. Energy & Fuels,2016,30(10):7858-7866. [38] VELIS C, WAGLAND S, LONGHURST P, et al. Solid recovered fuel: influence of waste stream composition and processing on chlorine content and fuel quality[J]. Environmental Science & Technology,2012,46(3):1923-1931. [39] BECKMANN M, POHL M, BERNHARDT D, et al. Criteria for solid recovered fuels as a substitute for fossil fuels: a review[J]. Waste Management & Research:the Journal for a Sustainable Circular Economy,2012,30(4):354-369. [40] NASRULLAH M, HURME M, OINAS P, et al. Influence of input waste feedstock on solid recovered fuel production in a mechanical treatment plant[J]. Fuel Processing Technology,2017,163:35-44. doi: 10.1016/j.fuproc.2017.03.034 [41] VAINIO E, YRJAS P, ZEVENHOVEN M, et al. The fate of chlorine, sulfur, and potassium during co-combustion of bark, sludge, and solid recovered fuel in an industrial scale BFB boiler[J]. Fuel Processing Technology,2013,105:59-68. doi: 10.1016/j.fuproc.2011.08.021 [42] WU H, GLARBORG P, FRANDSEN F J, et al. Co-combustion of pulverized coal and solid recovered fuel in an entrained flow reactor: general combustion and ash behaviour[J]. Fuel,2011,90(5):1980-1991. doi: 10.1016/j.fuel.2011.01.037 [43] SZYDEŁKO A, FERENS W, RYBAK W. The effect of mineral additives on the process of chlorine bonding during combustion and co-combustion of Solid Recovered Fuels[J]. Waste Management,2020,102:624-634. doi: 10.1016/j.wasman.2019.10.032 [44] LIU Z, WANG H Q, ZHANG X D, et al. Dechlorination of organochloride waste mixture by microwave irradiation before forming solid recovered fuel[J]. Waste Management,2017,62:118-124. doi: 10.1016/j.wasman.2016.11.022 [45] 罗建华. 机械生物法处理生活垃圾的分析与评述[J]. 中国资源综合利用,2006,24(2):19-21.LUO J H. Analysis and review on disposal of life-garbage by the machinical-biology disposal method[J]. China Resources Comprehensive Utilization,2006,24(2):19-21. □ -

下载:

下载: