Research progress on the application of steel slag for soil remediation

-

摘要:

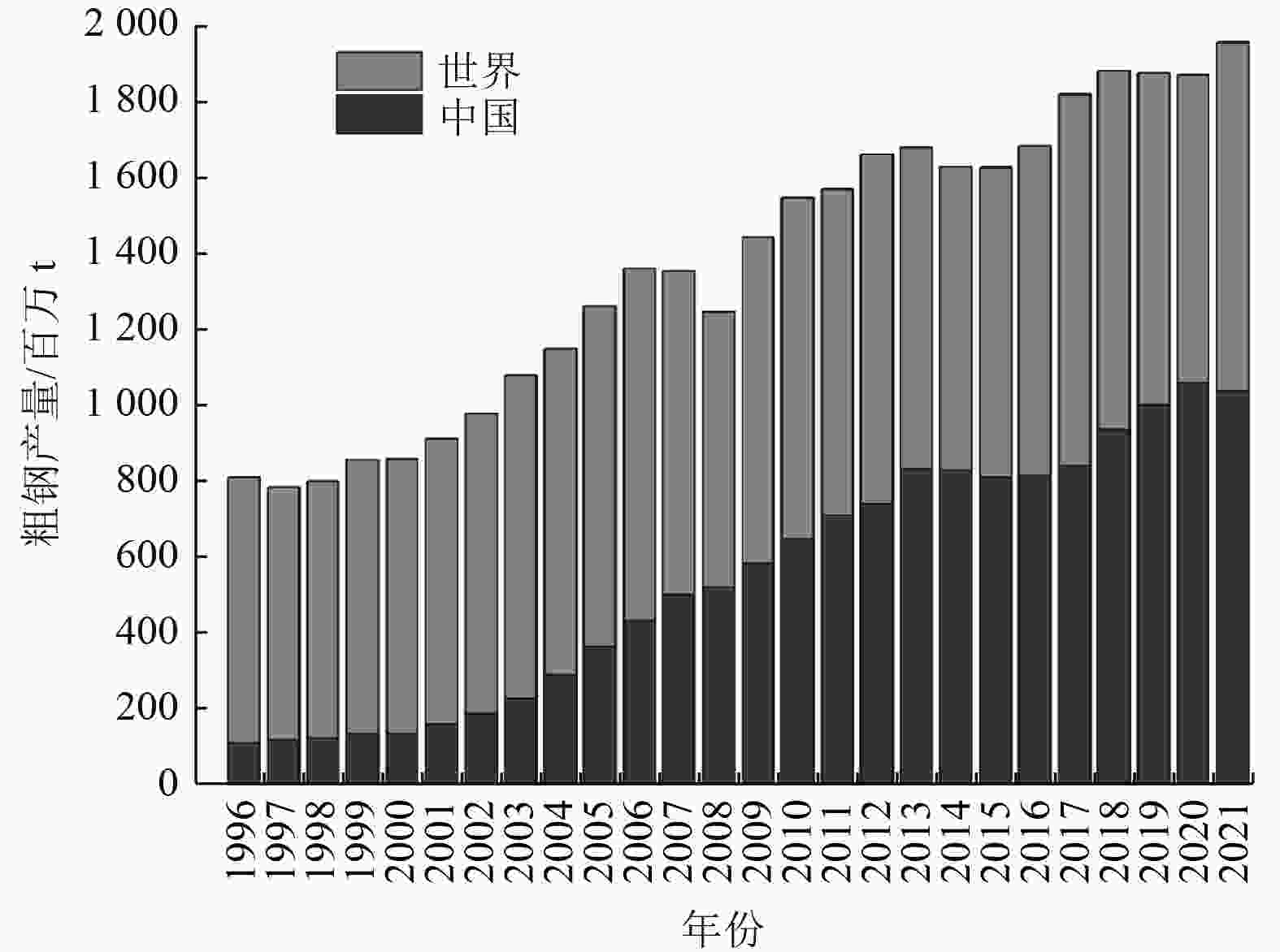

钢渣是钢铁行业制造生产中的副产物,大量未经处理的钢渣废弃堆积,不仅严重浪费资源还占据大量的土地资源,对周边土壤和环境造成污染,甚至对人类生产和生活产生极大威胁。目前我国钢铁行业钢渣产量快速增加,但钢渣综合利用率仅20%左右,而钢渣应用于土壤修复是固体废物处置与生态建设相结合的重要方向之一。在总结钢渣资源物理化学特性的基础上,概括了钢渣应用于土壤修复的基本原理和国内外研究现状。系统分析了钢渣作为土壤改良剂、土壤肥料及土壤重金属钝化剂的主要作用:钢渣作为土壤改良剂不仅可以改良酸化土壤还可以有效减轻温室气体的排放;作为土壤肥料可以为土壤提供微量元素和养分;作为土壤重金属钝化剂可以降低土壤中重金属含量。指出钢渣应用于土壤修复的潜力,同时也探讨了钢渣应用于农业土壤中所产生的环境影响并进行了风险评估,对钢渣应用于土壤修复未来的研究方向进行了展望。

Abstract:Steel slag is a by-product of the steel industry. A large amount of untreated steel slag waste is piled up, which not only seriously wastes resources but also occupies a large amount of land resources, thus causing pollution to the surrounding soil and environment, and even posing a major threat to human production and life. At present, the production of steel slag in China is increasing rapidly, but the comprehensive utilization rate of steel slag is only about 20%. Using steel slag for soil remediation is one of the important directions for combining solid waste disposal with ecological construction. Based on summarizing the physical and chemical properties of steel slag resources, the basic principles and status quo of using steel slag for soil remediation at home and abroad were summarized. The main functions of steel slag as a soil conditioner, soil fertilizer, and soil heavy metal passivator were systematically analyzed. Steel slag, as a soil conditioner, could not only improve acid soil but also effectively reduce greenhouse gas emissions. As a soil fertilizer, it could provide trace elements and nutrients for the soil, and as a soil heavy metal passivator, it could reduce the heavy metal content in soil. The potential of steel slag for soil remediation was pointed out, and the environmental impacts produced by steel slag used in agricultural soil were explored and the risk assessment was conducted. Finally, the future research direction for the application of steel slag in soil remediation was discussed.

-

Key words:

- steel slag /

- improver /

- fertilizer /

- soil remediation /

- adsorption /

- pollution

-

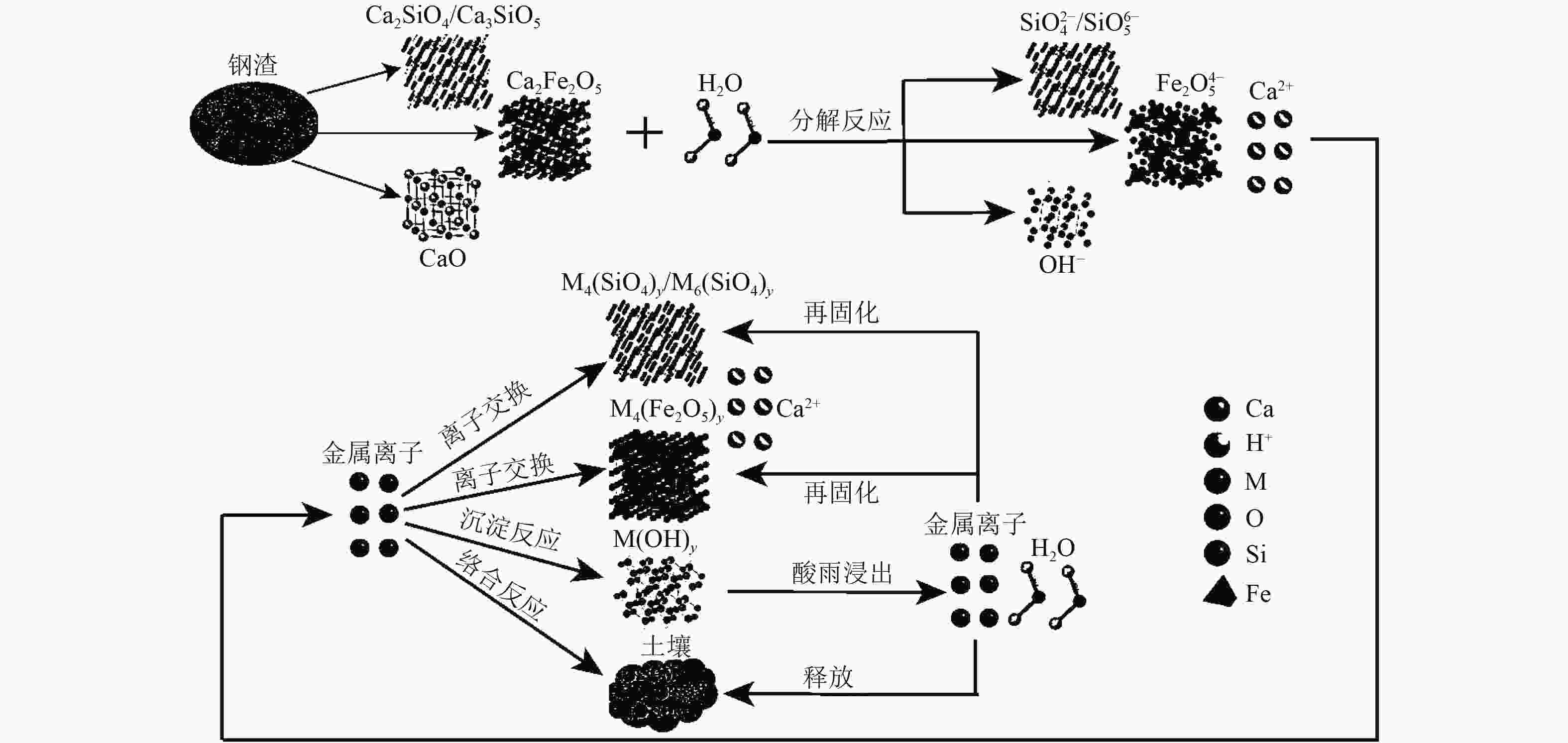

图 3 钢渣对土壤中重金属固化/稳定化机理[64]

Figure 3. Mechanism of heavy metal solidification/stabilization in soil by steel slag

表 1 钢渣基本性质及对应的利用方式

Table 1. Basic properties of steel slag and the corresponding utilization methods

性质 利用方式 坚硬、耐磨、塑性、粗糙 水利和道路建造 多孔、碱性 污水处理 含CaO、MgO、FeO、MnO等成分 熔剂 含C3S、C2S、C4AF组分 水泥和混凝土的改进 含CaO、MgO组分 CO2捕捉和烟气脱硫 含FeO、CaO、MgO、SiO2等组分 建筑用料、膏体填充 含肥料组分MgO、Fe2O3、CaO、SiO2 肥料和土壤改良 表 2 钢渣用于吸附重金属污染物

Table 2. Steel slag for adsorption of heavy metal contaminants

金属种类 比表面积/

(m2/g)孔径/mm 污染物初始浓度/

(mg/L)吸附参数 吸附效果

(去除率/吸附量)吸附剂用量/(g/L) 温度/℃ pH 吸附时间/h Ni2+[46] 10~100 2 20~38 1~11 4 92.15% Zn2+[47] 30.84 50~150 25~45 4~9 2.5 86 mg/g Cu2+[48] <0.6 1 000~4 000 2 20~40 <3.50 1 99.9% U6+[49] 8.61 10 3.3 25 4.00 3 98.5% Mn2+[50] 30.27 100 1 25 >6.00 10 97.37% Fe3+[51] 15.10 10 1.4 30 9~11 5/3 27.55 mg/g VO2 +[52] 0.9~2 100 5 25 1~11 1 080 96% MoO4 2−[53] 200 2 20 2~10 24 60% F-[54] <0.15 10~80 1 25~45 4~9 3 50.6 mg/g Cr3+/Zn2+[55] 500 0.5/1.2 25 >4.6/>6.8 22 85.79%/76.52% Pb2+/AsO4 3−[56] 20.28 444.6/288.5 20 7~10/8~9 18 99.5%/48.4% Cd2+/Mn2+[57] <10×10−3 10 2 25 8 1.5 98.37%/98.80% Cu2+/Pb2+/Zn2+[58] <45×10−3 100 25 3~5 20 244/273/508 mg/g Ni2+/H2PO4 −/NH4 +[59] 101) 2 25 6.7 24 3.56/3.28/2.21 mmol/g 1)单位为nmol/L。 -

[1] 饶磊. 转炉钢渣成分、结构及性能间内在规律及其应用研究[D]. 北京: 北京科技大学, 2020. [2] 沈鑫宇, 闫肖雅, 林杨, 等. 一种新型钢渣基免烧陶粒滤料的制备及其性能研究[J/OL]. 环境工程技术学报. doi: 10.12153/j.issn.1674-991X.20220709.SHEN X Y, YAN X Y, LIN Y, et al. Preparation and performance study of a new type of steel slag-based non-burned ceramsite filter media[J/OL]. Journal of Environmental Engineering Technology. doi: 10.12153/j.issn.1674-991X.20220709. [3] 杨丽, 石应杰, 张辰, 等.FeCl3改性钢渣脱除燃煤烟气中Hg0的研究[J]. 环境科学研究,2017,30(3):450-456.YANG L, SHI Y J, ZHANG C, et al. Fixed-bed studies of removing Hg0 from simulation flue gas by using FeCl3 composite materials[J]. Research of Environmental Sciences,2017,30(3):450-456. [4] 杨素洁, 张冰, 杨亚东, 等.钢渣综合利用现状研究[J]. 化工矿物与加工,2021,50(4):31-35. doi: 10.16283/j.cnki.hgkwyjg.2021.04.008YANG S J, ZHANG B, YANG Y D, et al. Research on the status of comprehensive utilization of steel slag[J]. Industrial Minerals & Processing,2021,50(4):31-35. doi: 10.16283/j.cnki.hgkwyjg.2021.04.008 [5] YI H, XU G P, CHENG H G, et al. An overview of utilization of steel slag[J]. Procedia Environmental Sciences,2012,16:791-801. doi: 10.1016/j.proenv.2012.10.108 [6] GUO J L, BAO Y P, WANG M. Steel slag in China: treatment, recycling, and management[J]. Waste Management,2018,78:318-330. doi: 10.1016/j.wasman.2018.04.045 [7] 黄毅, 徐国平, 程慧高, 等.典型钢渣的化学成分、显微形貌及物相分析[J]. 硅酸盐通报,2014,33(8):1902-1907. doi: 10.16552/j.cnki.issn1001-1625.2014.08.044HUANG Y, XU G P, CHENG H G, et al. Analysis on chemical composition, micro-morphology and phase of typical steel slag[J]. Bulletin of the Chinese Ceramic Society,2014,33(8):1902-1907. doi: 10.16552/j.cnki.issn1001-1625.2014.08.044 [8] 孔令种, 王珏, 陈来柱.钢渣成分变化对其矿物相及易磨性影响的研究[J]. 中国冶金,2013,23(4):56-59. doi: 10.13228/j.boyuan.issn1006-9356.2013.04.012KONG L Z, WANG J, CHEN L Z, et al. Research on mineral phase and grindability of steel slag by changing components contents[J]. China Metallurgy,2013,23(4):56-59. doi: 10.13228/j.boyuan.issn1006-9356.2013.04.012 [9] 朱金伟, 王凡, 任洪岩, 等.钢渣作为湿法脱硫吸收剂的实验研究[J]. 环境工程技术学报,2011,1(3):205-209. doi: 10.3969/j.issn.1674-991X.2011.03.033ZHU J W, WANG F, REN H Y, et al. Experimental study on steel slag used as wet flue gas desulfurization absorbent[J]. Journal of Environmental Engineering Technology,2011,1(3):205-209. doi: 10.3969/j.issn.1674-991X.2011.03.033 [10] LI Z B, ZHAO S Y, ZHAO X G, et al. Selective dissolution and cementitious property evaluation of converter steel slag[J]. Materials and Structures,2013,46(1):327-336. [11] FISHER L V, BARRON A R. The recycling and reuse of steelmaking slags: a review[J]. Resources, Conservation and Recycling,2019,146:244-255. doi: 10.1016/j.resconrec.2019.03.010 [12] 龙云飞, 牛秀萍, 冀欣, 等.混合钢渣路用性能研究[J]. 内蒙古工业大学学报(自然科学版),2022(2):159-165. doi: 10.13785/j.cnki.nmggydxxbzrkxb.2022.02.009LONG Y F, NIU X P, JI X, et al. A study on road performance of mixed steel slag[J]. Journal of Inner Mongolia University of Technology (Natural Science Edition),2022(2):159-165. doi: 10.13785/j.cnki.nmggydxxbzrkxb.2022.02.009 [13] 吴松芸.公路工程中钢渣应用研究[J]. 运输经理世界,2022(9):149-151. doi: 10.3969/j.issn.1673-3681.2022.09.050WU S Y. Study on application of steel slag in highway engineering[J]. Transport Business China,2022(9):149-151. doi: 10.3969/j.issn.1673-3681.2022.09.050 [14] SUZUKI M, YAMAMOTO T. Effect of steel-making slag addition on growth of the diatom Skeletonema costatum and the dinoflagellate Alexandrium tamarense[J]. Tetsu-to-Hagane,2005,91(10):783-787. doi: 10.2355/tetsutohagane1955.91.10_783 [15] 黄安林. 不同钝化材料及其复配对农田土壤中砷的钝化效果研究[D]. 海口: 海南大学, 2020. [16] 杨刚, 李辉, 陈华.钢渣微粉对重金属污染土壤的修复及机理研究[J]. 建筑材料学报,2021,24(2):318-322. doi: 10.3969/j.issn.1007-9629.2021.02.013YANG G, LI H, CHEN H. Remediation of heavy metals contaminated soil by steel slag powder and its mechanism[J]. Journal of Building Materials,2021,24(2):318-322. doi: 10.3969/j.issn.1007-9629.2021.02.013 [17] QASRAWI H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment[J]. Construction and Building Materials,2014,54:298-304. doi: 10.1016/j.conbuildmat.2013.12.063 [18] PANG L, LIAO S C, WANG D Q, et al. Influence of steel slag fineness on the hydration of cement-steel slag composite pastes[J]. Journal of Building Engineering,2022,57:104866. doi: 10.1016/j.jobe.2022.104866 [19] 陈亮.尾砂颗粒级配对水泥-钢渣基复合充填料浆流变特性及力学强度的影响[J]. 矿业研究与开发,2022,42(8):113-118. doi: 10.13827/j.cnki.kyyk.2022.08.028CHEN L. Effect of tailings particle size on rheological properties and mechanical strength of cement-steel slag-based composite filling slurry[J]. Mining Research and Development,2022,42(8):113-118. doi: 10.13827/j.cnki.kyyk.2022.08.028 [20] POPESCU L, ZAMAN F, VOLCEANOV E, et al. Assessment on lf slags characteristics used for agricultural acidic soils improvement[J]. Revista Romana de Materiale-Romanian Journal of Materials,2014,44(2):141-146. [21] KONG F Y, YING Y Q, LU S G. Heavy metal pollution risk of desulfurized steel slag as a soil amendment in cycling use of solid wastes[J]. Journal of Environmental Sciences,2023,127:349-360. doi: 10.1016/j.jes.2022.05.010 [22] DAS S, KIM G W, HWANG H Y, et al. Cropping with slag to address soil, environment, and food security[J]. Frontiers in Microbiology,2019,10:1320. doi: 10.3389/fmicb.2019.01320 [23] WANG W Q, LAI D, ABID A, et al. Effects of steel slag and biochar incorporation on active soil organic carbon pools in a subtropical paddy field[J]. Agronomy,2018,8(8):135. doi: 10.3390/agronomy8080135 [24] CHANG E E, PAN S Y, CHEN Y H, et al. CO2 sequestration by carbonation of steelmaking slags in an autoclave reactor[J]. Journal of Hazardous Materials,2011,195:107-114. doi: 10.1016/j.jhazmat.2011.08.006 [25] WANG M Y, LAN X F, XU X P, et al. Steel slag and biochar amendments decreased CO2 emissions by altering soil chemical properties and bacterial community structure over two-year in a subtropical paddy field[J]. Science of the Total Environment,2020,740:140403. doi: 10.1016/j.scitotenv.2020.140403 [26] KUMAR S S, KUMAR A, SINGH S, et al. Industrial wastes: fly ash, steel slag and phosphogypsum- potential candidates to mitigate greenhouse gas emissions from paddy fields[J]. Chemosphere,2020,241:124824. doi: 10.1016/j.chemosphere.2019.124824 [27] KUNHIKRISHNAN A, THANGARAJAN R, BOLAN N S, et al. Functional relationships of soil acidification, liming, and greenhouse gas flux[M]//Advances in Agronomy. Amsterdam: Elsevier, 2016: 1-71. [28] WANG W, SARDANS J, LAI D Y F, et al. Effects of steel slag application on greenhouse gas emissions and crop yield over multiple growing seasons in a subtropical paddy field in China[J]. Field Crops Research,2015,171:146-156. doi: 10.1016/j.fcr.2014.10.014 [29] BAGGS E M. Soil microbial sources of nitrous oxide: recent advances in knowledge, emerging challenges and future direction[J]. Current Opinion in Environmental Sustainability,2011,3(5):321-327. doi: 10.1016/j.cosust.2011.08.011 [30] SINGLA A, INUBUSHI K. Effect of slag-type fertilizers on N2O flux from komatsuna vegetated soil and CH4 flux from paddy vegetated soil[J]. Paddy and Water Environment,2015,13(1):43-50. doi: 10.1007/s10333-013-0405-z [31] CHEN J, XING Y, WANG Y, et al. Application of iron and steel slags in mitigating greenhouse gas emissions: a review[J]. Science of the Total Environment,2022,844:157041. doi: 10.1016/j.scitotenv.2022.157041 [32] MAMATHA D, GOWDA R C, SHIVAKUMARA M N. Effect of basic slag and lime on chemical properties of acid soil[J]. Emergent Life Sciences Research,2019,5(2):8-11. doi: 10.31783/elsr.2019.520811 [33] 魏贤. 钢渣对不同轮作制度酸性土壤改良效果及其安全性评价[D]. 武汉: 华中农业大学, 2015. [34] WEN T T, YANG L Y, DANG C Y, et al. Effect of basic oxygen furnace slag on succession of the bacterial community and immobilization of various metal ions in acidic contaminated mine soil[J]. Journal of Hazardous Materials,2020,388:121784. doi: 10.1016/j.jhazmat.2019.121784 [35] 况琴, 吴山, 黄庭, 等.生物质炭和钢渣对江西丰城典型富硒区土壤硒有效性的调控效果与机理研究[J]. 岩矿测试,2019,38(6):705-714. doi: 10.15898/j.cnki.11-2131/td.201901190014KUANG Q, WU S, HUANG T, et al. Effect and mechanism of biomass carbon and steel slag as ameliorants on soil selenium availability in a typical Se-rich area of Fengcheng City, Jiangxi Province[J]. Rock and Mineral Analysis,2019,38(6):705-714. doi: 10.15898/j.cnki.11-2131/td.201901190014 [36] LEÓN-ROMERO M A, SOTO-RÍOS P C, NOMURA M, et al. Effect of steel slag to improve soil quality of tsunami-impacted land while reducing the risk of heavy metal bioaccumulation[J]. Water, Air, & Soil Pollution,2018,229(1):12. [37] ZHA Y H, LI C H, WANG Z R. Research progress on application of steel slag in agriculture[C]//Characterization of Minerals, Metals, and Materials 2021. Cham: Springer, 2021: 165-175. [38] DAS S, GWON H S, KHAN M I, et al. Steel slag amendment impacts on soil microbial communities and activities of rice (Oryza sativa L. )[J]. Scientific Reports,2020,10(1):6746. doi: 10.1038/s41598-020-63783-1 [39] SCHALLER J, FAUCHERRE S, JOSS H, et al. Silicon increases the phosphorus availability of Arctic soils[J]. Scientific Reports,2019,9(1):1-11. doi: 10.1038/s41598-018-37186-2 [40] JIAO Y, GRANT C A, BAILEY L D. Effects of phosphorus and zinc fertilizer on cadmium uptake and distribution in flax and durum wheat[J]. Journal of the Science of Food and Agriculture,2004,84(8):777-785. doi: 10.1002/jsfa.1648 [41] HOSSEINI S, SOLTANI S M, FENNELL P S, et al. Production and applications of electric-arc-furnace slag as solid waste in environmental technologies: a review[J]. Environmental Technology Reviews,2016,5(1):1-11. doi: 10.1080/21622515.2016.1147615 [42] NING D F, LIANG Y C, LIU Z D, et al. Impacts of steel-slag-based silicate fertilizer on soil acidity and silicon availability and metals-immobilization in a paddy soil[J]. PLoS One,2016,11(12):e0168163. doi: 10.1371/journal.pone.0168163 [43] 王晓军, 高洪生, 张磊, 等.钢渣硅肥在白菜种植中的应用[J]. 北方园艺,2018(22):18-22.WANG X J, GAO H S, ZHANG L, et al. Application of slag calcium silicate fertilizer in Chinese cabbage planting[J]. Northern Horticulture,2018(22):18-22. [44] 王昭然, 于巧娣, 李灿华, 等.钢渣-锰渣复混肥的制备、结构与性能[J]. 中国冶金,2021,31(1):75-80. doi: 10.13228/j.boyuan.issn1006-9356.20200336WANG Z R, YU Q D, LI C H, et al. Preparation, structure and performance of steel slag-manganese slag compound fertilizer[J]. China Metallurgy,2021,31(1):75-80. doi: 10.13228/j.boyuan.issn1006-9356.20200336 [45] 赵玉潮, 鲍仁冬, 曾香梅.转炉钢渣在污染物治理和生态修复中的应用[J]. 工业安全与环保,2018,44(8):92-94. doi: 10.3969/j.issn.1001-425X.2018.08.026ZHAO Y C, BAO R D, ZENG X M. Application of converter steel slag in pollution control and ecological restoration[J]. Industrial Safety and Environmental Protection,2018,44(8):92-94. doi: 10.3969/j.issn.1001-425X.2018.08.026 [46] ORTIZ N, PIRES M A F, BRESSIANI J C. Use of steel converter slag as nickel adsorber to wastewater treatment[J]. Waste Management,2001,21(7):631-635. doi: 10.1016/S0956-053X(00)00123-9 [47] SARKAR C, BASU J K, SAMANTA A N. Synthesis of mesoporous geopolymeric powder from LD slag as superior adsorbent for Zinc(Ⅱ) removal[J]. Advanced Powder Technology,2018,29(5):1142-1152. doi: 10.1016/j.apt.2018.02.005 [48] XUE Y J, WU S P, ZHOU M. Adsorption characterization of Cu(Ⅱ) from aqueous solution onto basic oxygen furnace slag[J]. Chemical Engineering Journal,2013,231:355-364. doi: 10.1016/j.cej.2013.07.045 [49] CHEN Q, WANG H Q, HU E M, et al. Efficient adsorption of uranium(Ⅵ) from aqueous solution by a novel modified steel slag adsorbent[J]. Journal of Radioanalytical and Nuclear Chemistry,2020,323(1):73-81. doi: 10.1007/s10967-019-06848-4 [50] ZAHAR M S M, KUSIN F M, MUHAMMAD S N. Adsorption of Manganese in aqueous solution by steel slag[J]. Procedia Environmental Sciences,2015,30:145-150. doi: 10.1016/j.proenv.2015.10.026 [51] SAMANTA N S, BANERJEE S, MONDAL P, et al. Preparation and characterization of zeolite from waste Linz-Donawitz (LD) process slag of steel industry for removal of Fe3+ from drinking water[J]. Advanced Powder Technology,2021,32(9):3372-3387. doi: 10.1016/j.apt.2021.07.023 [52] LIAN J J, XU S G, CHANG N B, et al. Removal of molybdenum (Ⅵ) from mine tailing effluents with the aid of loessial soil and slag waste[J]. Environmental Engineering Science,2013,30(5):213-220. doi: 10.1089/ees.2011.0441 [53] GAO Y C, JIANG J G, TIAN S C, et al. BOF steel slag as a low-cost sorbent for vanadium(Ⅴ) removal from soil washing effluent[J]. Scientific Reports,2017,7(1):1-10. doi: 10.1038/s41598-016-0028-x [54] SARKAR C, BASU J K, SAMANTA A N. Experimental and kinetic study of fluoride adsorption by Ni and Zn modified LD slag based geopolymer[J]. Chemical Engineering Research and Design,2019,142:165-175. doi: 10.1016/j.cherd.2018.12.006 [55] CHEN G L, YANG L Y, CHEN J, et al. Competitive mechanism and influencing factors for the simultaneous removal of Cr(Ⅲ) and Zn(Ⅱ) in acidic aqueous solutions using steel slag: batch and column experiments[J]. Journal of Cleaner Production,2019,230:69-79. doi: 10.1016/j.jclepro.2019.04.402 [56] KIM S H, CHUNG H, JEONG S, et al. Identification of pH-dependent removal mechanisms of lead and arsenic by basic oxygen furnace slag: relative contribution of precipitation and adsorption[J]. Journal of Cleaner Production,2021,279:123451. doi: 10.1016/j.jclepro.2020.123451 [57] ABD EL-AZIM H, EL-SAYED SELEMAN M M, SAAD E M. Applicability of water-spray electric arc furnace steel slag for removal of Cd and Mn ions from aqueous solutions and industrial wastewaters[J]. Journal of Environmental Chemical Engineering,2019,7(2):102915. doi: 10.1016/j.jece.2019.102915 [58] SHAO N N, TANG S Q, LIU Z, et al. Hierarchically structured calcium silicate hydrate-based nanocomposites derived from steel slag for highly efficient heavy metal removal from wastewater[J]. ACS Sustainable Chemistry & Engineering,2018,6(11):14926-14935. [59] KADIROVA Z C, HOJAMBERDIEV M, BO L L, et al. Simultaneous removal of NH4 +, H2PO4 − and Ni2+ from aqueous solution by thermally activated combinations of steel converter slag and spent alumina catalyst[J]. Journal of Water Process Engineering,2015,8:151-159. doi: 10.1016/j.jwpe.2015.10.004 [60] DIMITROVA S V, MEHANDGIEV D R. Lead removal from aqueous solutions by granulated blast-furnace slag[J]. Water Research,1998,32(11):3289-3292. doi: 10.1016/S0043-1354(98)00119-5 [61] DUAN J M, SU B. Removal characteristics of Cd(Ⅱ) from acidic aqueous solution by modified steel-making slag[J]. Chemical Engineering Journal,2014,246:160-167. doi: 10.1016/j.cej.2014.02.056 [62] KOSTURA B, KULVEITOVÁ H, LEŠKO J. Blast furnace slags as sorbents of phosphate from water solutions[J]. Water Research,2005,39(9):1795-1802. doi: 10.1016/j.watres.2005.03.010 [63] DIMITROVA S V, MEHANJIEV D R. Interaction of blast-furnace slag with heavy metal ions in water solutions[J]. Water Research,2000,34(6):1957-1961. doi: 10.1016/S0043-1354(99)00328-0 [64] YANG L Y, WEI T C, LI S W, et al. Immobilization persistence of Cu, Cr, Pb, Zn ions by the addition of steel slag in acidic contaminated mine soil[J]. Journal of Hazardous Materials,2021,412:125176. doi: 10.1016/j.jhazmat.2021.125176 [65] O'CONNOR J, NGUYEN T B T, HONEYANDS T, et al. Production, characterisation, utilisation, and beneficial soil application of steel slag: a review[J]. Journal of Hazardous Materials,2021,419:126478. doi: 10.1016/j.jhazmat.2021.126478 [66] MEHARG C, MEHARG A A. Silicon, the silver bullet for mitigating biotic and abiotic stress, and improving grain quality, In rice[J]. Environmental and Experimental Botany,2015,120:8-17. doi: 10.1016/j.envexpbot.2015.07.001 [67] GU H H, QIU H, TIAN T, et al. Mitigation effects of silicon rich amendments on heavy metal accumulation in rice (Oryza sativa L.) planted on multi-metal contaminated acidic soil[J]. Chemosphere,2011,83(9):1234-1240. doi: 10.1016/j.chemosphere.2011.03.014 [68] 谷海红, 李忠伟, 俞强.钢渣对酸性重金属污染土壤的修复研究进展[J]. 中国农学通报,2012,28(20):243-249. doi: 10.11924/j.issn.1000-6850.2012-1859GU H H, LI Z W, YU Q. A review of the effects of steel slag on remediation of heavy metal contaminated acidic soil[J]. Chinese Agricultural Science Bulletin,2012,28(20):243-249. doi: 10.11924/j.issn.1000-6850.2012-1859 [69] HE H D, TAM N F Y, YAO A J, et al. Growth and Cd uptake by rice (Oryza sativa) in acidic and Cd-contaminated paddy soils amended with steel slag[J]. Chemosphere,2017,189:247-254. doi: 10.1016/j.chemosphere.2017.09.069 [70] GWON H S, KHAN M I, ALAM M A, et al. Environmental risk assessment of steel-making slags and the potential use of LD slag in mitigating methane emissions and the grain arsenic level in rice (Oryza sativa L. )[J]. Journal of Hazardous Materials,2018,353:236-243. doi: 10.1016/j.jhazmat.2018.04.023 [71] WANG X B, LI X Y, YAN X, et al. Environmental risks for application of iron and steel slags in soils in China: a review[J]. Pedosphere,2021,31(1):28-42. doi: 10.1016/S1002-0160(20)60058-3 [72] 朱苗淼, 朱武卫.矿渣与工业废渣改良黄土的性能与机理研究进展[J]. 灾害学,2022,37(1):129-133. doi: 10.3969/j.issn.1000-811X.2022.01.022ZHU M M, ZHU W W. Research progress on properties and mechanism of loess modified by slag and industrial waste residue[J]. Journal of Catastrophology,2022,37(1):129-133. □ doi: 10.3969/j.issn.1000-811X.2022.01.022 -

下载:

下载: