Optimizing the pathways of industrial solid waste recycling under multiple perspectives: a case study of copper smelting slag

-

摘要:

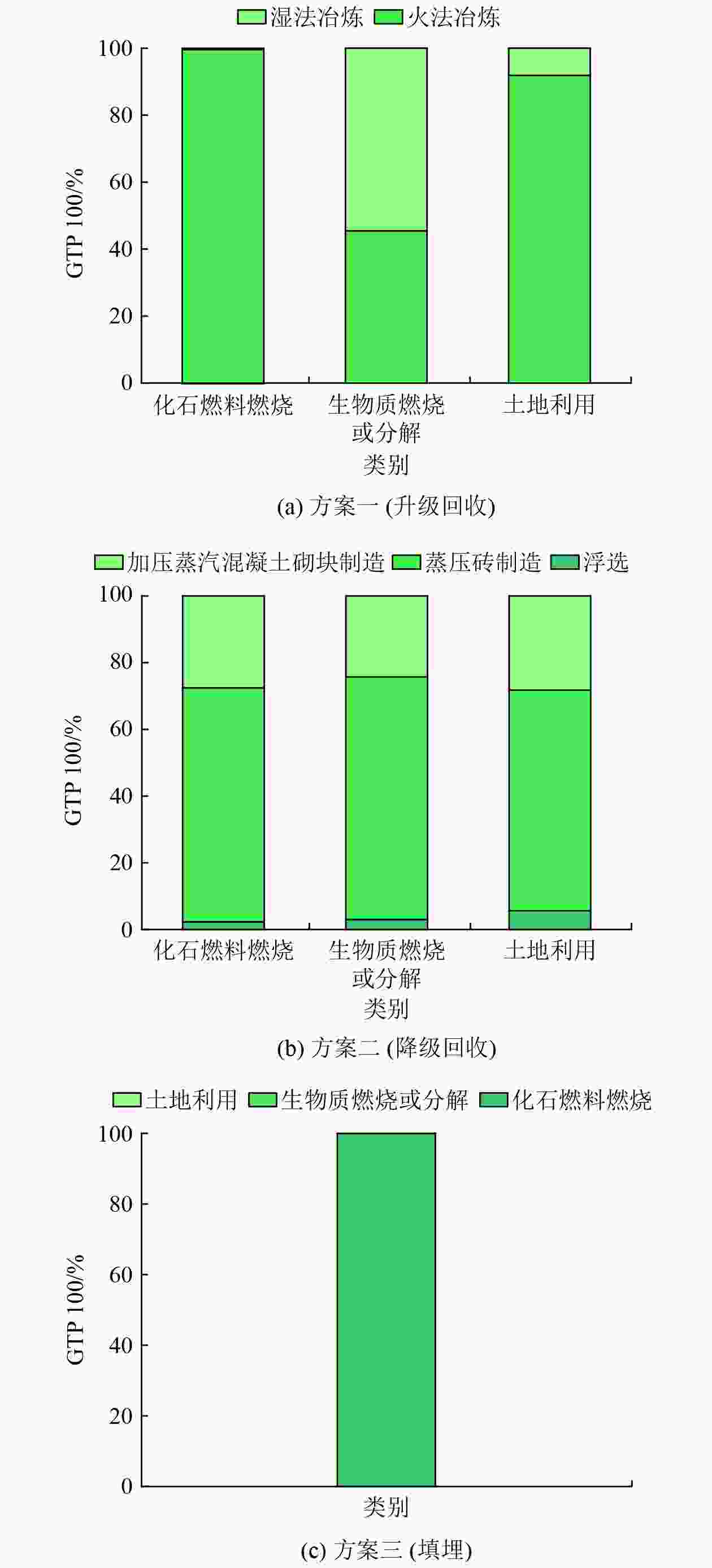

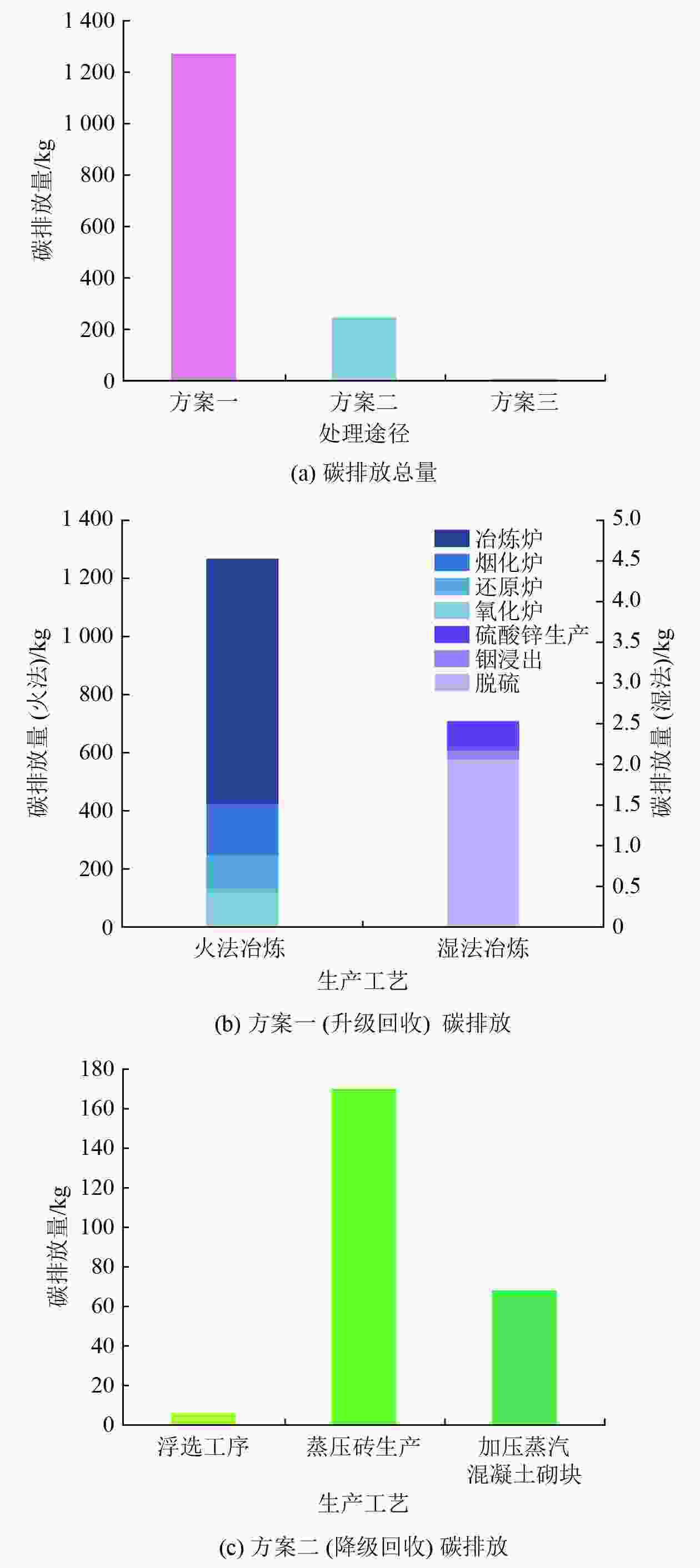

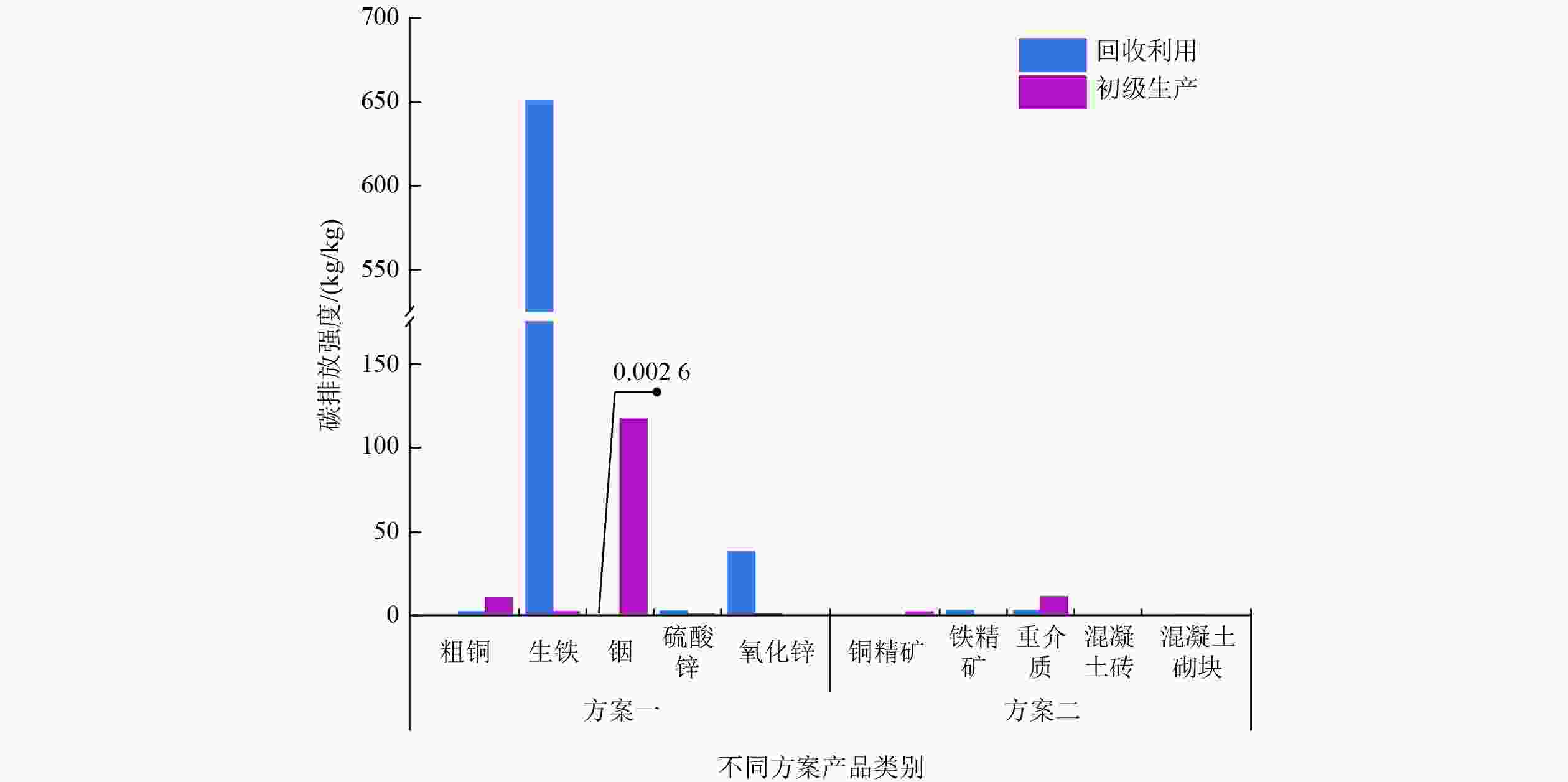

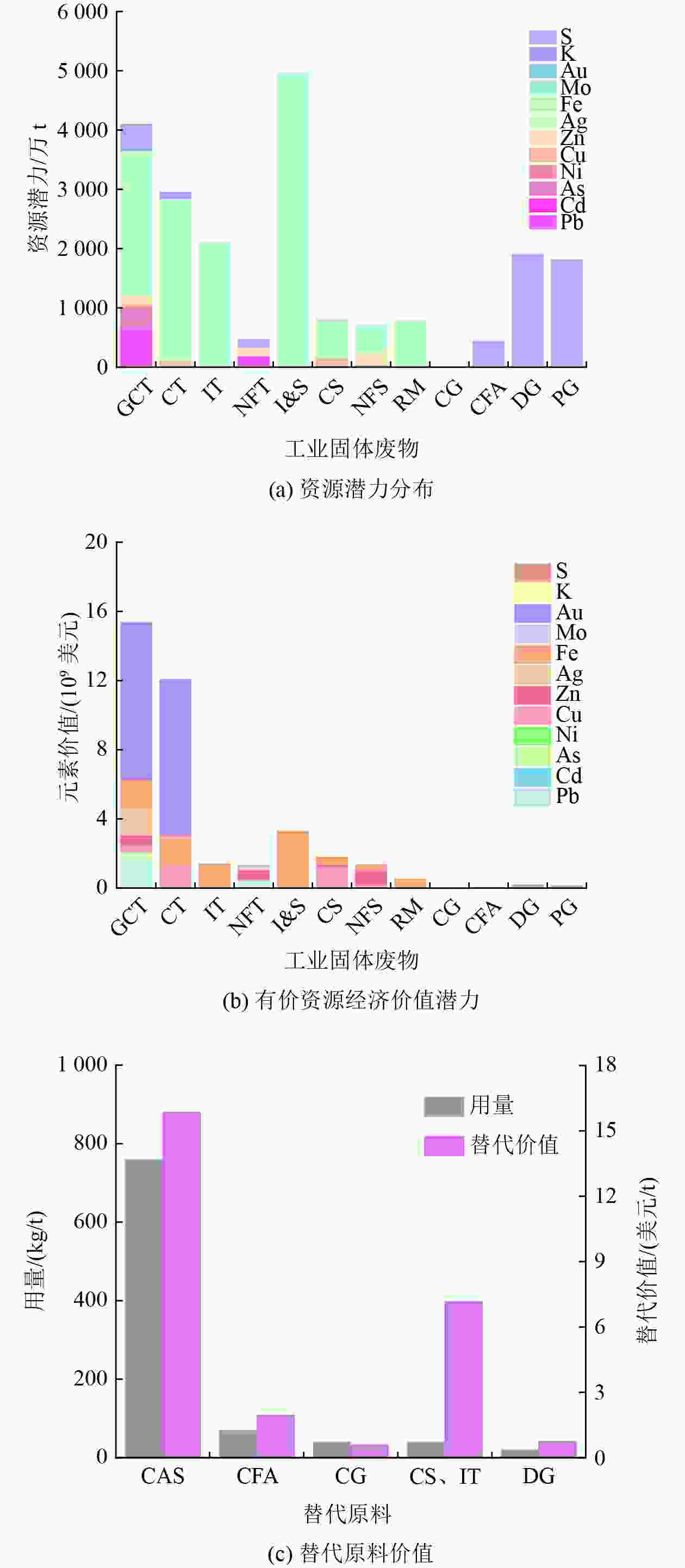

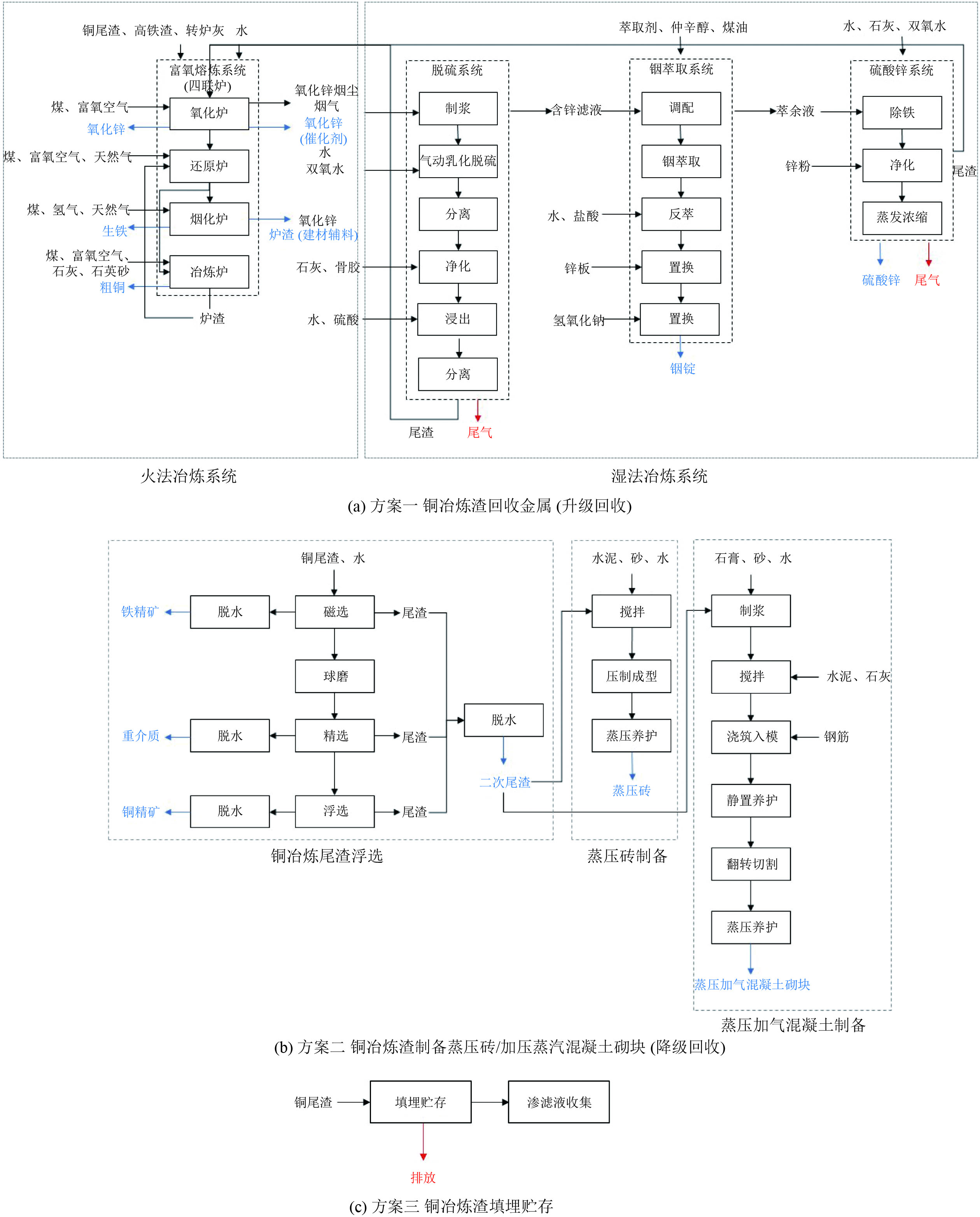

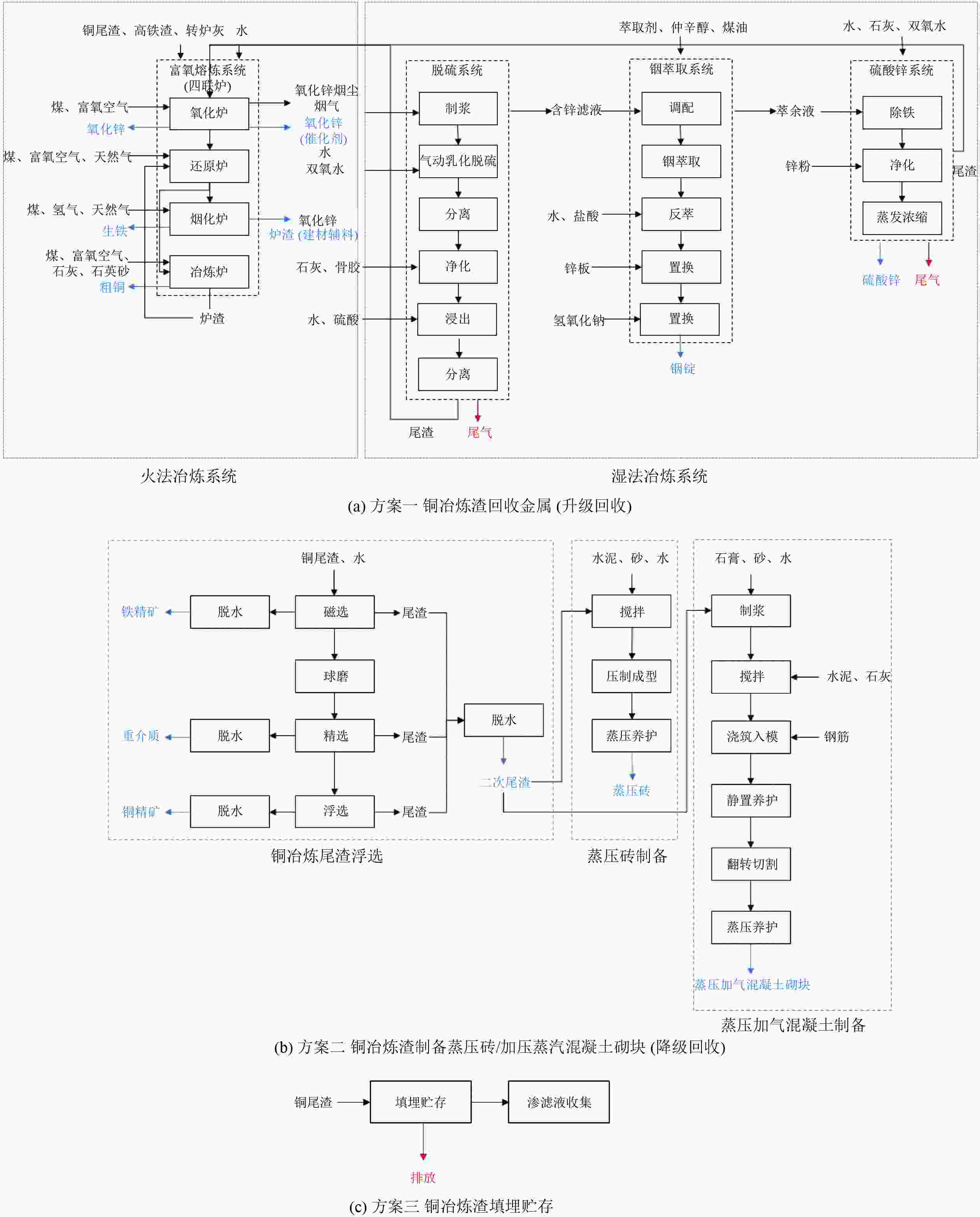

为降低工业固体废物处理处置过程对环境和气候变化影响,提高资源利用率,基于环境资源交互属性、生命周期评价和有价资源价值评估3项指标,建立多维度工业固体废物资源化利用路径优化方法。结果表明:通过升级回收和降级回收的资源化途径,工业固体废物的生态毒性和人体健康毒性较填埋途径分别降低96.86%和98.53%,能够减少土壤污染,维护土壤生态安全。预计2035年铜冶炼渣升级回收、降级回收和原级回收的比例分别达到30%、50%和10%时,可以实现最优目标,但升级回收占比的提高会导致碳排放升高和综合效益下降。研究结果表明,短期内降级回收能够大规模消纳工业固体废物,但受到建筑行业和产品质量管理制约。因此,远期规划需合理分配工业固体废物资源化途径占比,以获得最大化环境效益和经济效益。

Abstract:To mitigate the environmental and climate impacts of industrial solid waste management and disposal processes, and to enhance recycling efficiency, this study developed a multidimensional optimization method for the recycling of industrial waste. The method integrated three indicators: environmental-resource interaction attribute, life cycle assessment, and economic resource value assessment. The findings indicated that compared to landfill methods, recycling pathways through upcycling and downcycling of industrial solid waste significantly reduced ecotoxicity and human health toxicity by 96.86% and 98.53%, respectively. The method can also diminish soil pollution and preserve soil ecological health. It was anticipated that by 2035, the proportions of upcycling, downcycling, and reuse of copper smelting slag would reach 30%, 50%, and 10%, respectively, achieving optimal target values. However, an increased proportion of upcycling would lead to higher carbon emissions and reduced overall benefits. Based on these results, downcycling could process a large volume of industrial solid waste in the short term but was constrained by the construction industry and product quality management. Therefore, long-term planning requires rationally allocating the proportions of industrial solid waste recycling pathways to maximize environmental and economic benefits.

-

Key words:

- industrial solid waste /

- recycling /

- carbon emission /

- soil pollution /

- pathway optimization

-

表 1 铜冶炼渣不同处理途径生命周期影响评价结果

Table 1. Results of life cycle assessment of copper smelting slag treatment in different pathways

影响类别 单位 升级回收 降级回收 填埋 特征化值 标准化值 特征化值 标准化值 特征化值 标准化值 金属资源耗竭 kg (以Sb当量计) 1.59 9.33×10−10 0.975 5.70×10−10 0.123 7.17×10−11 酸化 kg (以SO2当量计) 6.25 9.32×10−9 0.713 1.06×10−9 0.056 3 8.39×10−11 富营养化 kg (以PO4当量计) 0.217 4.33×10−10 0.169 3.36×10−10 0.011 6 2.31×10−11 全球变暖潜势 kg (以CO2当量计) 1 584.08 6.27×10−9 241.75 9.57×10−10 7.98 3.16×10−11 臭氧层消化 kg (以CFC-11当量计) 2.99×10−5 3.05×10−11 1.02×10−5 1.04×10−11 2.81×10−6 2.87×10−12 人体毒性 kg (以1,4-DB当量计) 4 827.3 2.57×10−8 126.34 6.72×10−10 4 792.91 2.55×10−8 淡水生态毒性 kg (以1,4-DB当量计) 30.65 4.08×10−9 47.66 6.34×10−9 3 192.12 4.25×10−7 陆地生态毒性 kg (以1,4-DB当量计) 1.56 1.71×10−9 0.458 4.99×10−10 0.900 9.81×10−10 淡水沉积物生态毒性 kg(以1,4-DB当量计) 69.20 6.78×10−9 106.30 1.04×10−8 7851.41 7.69×10−7 光化学氧化 kg (以C2H4当量计) 5.77 3.17×10−8 0.036 2 1.99×10−10 0.003 40 1.87×10−11 资源损耗1) MJ 257.32 0.046 142.47 0.025 5 20.95 0.003 75 1)采用Eco-indicator 99(E)方法单独计算。 表 2 多目标线性优化指标值清单

Table 2. Multi-objective linear programming index list

方案 ERIA

(bit−1)碳排放/

kg(以CO2当量计)ERVA

(元/t)升级回收 25.25 1 270.30 495.92 原级回收 32.29 756.97 342.87 降级回收 285.47 243.63 189.82 填埋处置 2.68 7.97 0 注:升级回收、降级回收、填埋过程碳排放和经济价值采用本研究计算结果表征,原级回收方式未设置实际案例,实际工业生产中,铜冶炼渣回收制备化学制品、新材料等途径适用于该方案情景,其碳排放和经济价值采用升级回收和降级回收均值表征。ERIA使用以往研究所得结果表征。 -

[1] XU J H, GUAN Y R, OLDFIELD J, et al. China carbon emission accounts 2020-2021[J]. Applied Energy,2024,360:122837. doi: 10.1016/j.apenergy.2024.122837 [2] 中共中央 国务院. 中共中央 国务院关于全面推进美丽中国建设的意见[A/OL]. [2024-04-20]. https://www.gov.cn/gongbao/2024/issue_11126/202401/content_6928805.html. [3] ZHU J M, CHERTOW M R. Greening industrial production through waste recovery: "comprehensive utilization of resources" in China[J]. Environmental Science & Technology,2016,50(5):2175-2182. [4] 国务院办公厅. 国务院办公厅关于加快构建废弃物循环利用体系的意见[A/OL]. (2024-02-09)[2024-04-20]. https://www.gov.cn/zhengce/zhengceku/202402/content_6931080.htm. [5] ZENG X L, GONG R Y, CHEN W Q, et al. Uncovering the recycling potential of "new" WEEE in China[J]. Environmental Science & Technology,2016,50(3):1347-1358. [6] KANWAL Q, LI J H, ZENG X L. Mapping recyclability of industrial waste for anthropogenic circularity: a circular economy approach[J]. ACS Sustainable Chemistry & Engineering,2021,9(35):11927-11936. [7] 辛宝平, 王佳. 涉重危废三维属性及其精细化分级分类体系[J]. 环境工程学报,2022,16(2):355-362.XIN B P, WANG J. Three-dimensional properties of hazardous wastes containing heavy metals and their refined classification and grading system[J]. Chinese Journal of Environmental Engineering,2022,16(2):355-362. [8] 黄文博, 李金惠, 曾现来. 固体废物无害化精准定量评估及科学启示: 以典型工业废物为例[J]. 科学通报,2022,67(7):685-696.HUANG W B, LI J H, ZENG X L. Accurately quantifying the detoxication of solid waste and its scientific insights: the case of typical industrial waste[J]. Chinese Science Bulletin,2022,67(7):685-696. [9] WANG Y X, LEVIS J W, BARLAZ M A. Life-cycle assessment of a regulatory compliant U. S. municipal solid waste landfill[J]. Environmental Science & Technology,2021,55(20):13583-13592. [10] ZHANG Y, JI Y J, XU H, et al. Life cycle assessment of valuable metal extraction from copper pyrometallurgical solid waste[J]. Resources, Conservation and Recycling,2023,191:106875. doi: 10.1016/j.resconrec.2023.106875 [11] di MAIO F, REM P C, BALDÉ K, et al. Measuring resource efficiency and circular economy: a market value approach[J]. Resources, Conservation and Recycling,2017,122:163-171. doi: 10.1016/j.resconrec.2017.02.009 [12] PENG X X, JIANG Y S, CHEN Z H, et al. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: a review[J]. Environmental Chemistry Letters,2023,21(2):765-801. doi: 10.1007/s10311-022-01551-5 [13] 谢明辉, 满贺诚, 段华波, 等. 生命周期影响评价方法及本地化研究进展[J]. 环境工程技术学报,2022,12(6):2148-2156.XIE M H, MAN H C, DUAN H B, et al. Research progress on the life cycle impact assessment methods and their localization in China[J]. Journal of Environmental Engineering Technology,2022,12(6):2148-2156. [14] WANG X, LI C, LAM C H, et al. Emerging waste valorisation techniques to moderate the hazardous impacts, and their path towards sustainability[J]. Journal of Hazardous Materials, 2022, 423(Pt A): 127023. [15] FARAGÒ M, DAMGAARD A, MADSEN J A, et al. From wastewater treatment to water resource recovery: environmental and economic impacts of full-scale implementation[J]. Water Research,2021,204:117554. doi: 10.1016/j.watres.2021.117554 [16] 温宗国, 唐岩岩, 王俊博, 等. 新时代循环经济发展助力美丽中国建设的路径与方向[J]. 中国环境管理,2022,14(6):33-41.WEN Z G, TANG Y Y, WANG J B, et al. The development of circular economy in the new era has helped to build a beautiful China[J]. Chinese Journal of Environmental Management,2022,14(6):33-41. [17] 张旅, 杨建新, 刘晶茹, 等. 基于生命周期评价的铜尾渣资源化利用环境效益: 以制取蒸压砖为例[J]. 岩石矿物学杂志,2022,41(5):950-958.ZHANG L, YANG J X, LIU J R, et al. Environmental benefit of copper tailings resource utilization based on life cycle assessment: a case study of autoclaved bricks production[J]. Acta Petrologica et Mineralogica,2022,41(5):950-958. [18] ADRIANTO L R, PFISTER S. Prospective environmental assessment of reprocessing and valorization alternatives for sulfidic copper tailings[J]. Resources, Conservation and Recycling,2022,186:106567. doi: 10.1016/j.resconrec.2022.106567 [19] ADRIANTO L R, CIACCI L, PFISTER S, et al. Toward sustainable reprocessing and valorization of sulfidic copper tailings: Scenarios and prospective LCA[J]. Science of the Total Environment,2023,871:162038. doi: 10.1016/j.scitotenv.2023.162038 [20] 肖文革, 牛飞, 王立, 等. 正丁基黄原酸钠干燥品的生产工艺研究[J]. 有色矿冶,2016,32(3):16-17. doi: 10.3969/j.issn.1007-967X.2016.03.005XIAO W G, NIU F, WANG L, et al. The Analysis of the Production Technology for Sodium Butyl Xanthate(dry pellet)[J]. Non-Ferrous Mining and Metallurgy,2016,32(3):16-17. doi: 10.3969/j.issn.1007-967X.2016.03.005 [21] YOUSEFLOO A, BABAZADEH R. Designing an integrated municipal solid waste management network: a case study[J]. Journal of Cleaner Production,2020,244:118824. doi: 10.1016/j.jclepro.2019.118824 [22] JO Y S, JANG Y S. Comparison of waste settlement characteristics for two landfills disposed in long sequential periods[J]. Waste Management,2021,131:433-442. doi: 10.1016/j.wasman.2021.07.003 [23] 刘奇汶, 毕莹莹, 董黎明, 等. 基于生命周期评价的原生和再生PET纤维环境影响对比分析[J]. 环境工程技术学报,2023,13(4):1635-1642.LIU Q W, BI Y Y, DONG L M, et al. Comparative analysis of the environmental impact of virgin and recycled PET fibers based on life cycle assessment[J]. Journal of Environmental Engineering Technology,2023,13(4):1635-1642. [24] ZENG X L, ALI S H, TIAN J P, et al. Mapping anthropogenic mineral generation in China and its implications for a circular economy[J]. Nature Communications,2020,11(1):1544. doi: 10.1038/s41467-020-15246-4 [25] 陈曦, 代文彬, 陈学刚, 等. 有色冶金渣的资源化利用研究现状[J]. 有色冶金节能,2022,38(5):9-15.CHEN X, DAI W B, CHEN X G, et al. Research status of resource utilization of nonferrous metallurgical slag[J]. Energy Saving of Nonferrous Metallurgy,2022,38(5):9-15. [26] 国家发展和改革委员会, 科学技术部, 工业和信息化部, 等. 关于“十四五”大宗固体废弃物综合利用的指导意见[A/OL]. (2021-03-18)[2024-04-20]. https://www.gov.cn/zhengce/zhengceku/2021-03/25/content_5595566.htm. [27] 工业和信息化部, 国家发展和改革委员会, 科学技术部, 等. 关于加快推动工业资源综合利用的实施方案[A/OL]. [2024-04-20]. https://www.miit.gov.cn/cms_files/filemanager/1226211233/attach/202112/d592a0f95c10417a8340d647c780efa5.pdf. ⊕ -

下载:

下载: